This Content Is Only For Subscribers

Authors: D.T. Pio, A.C.M Vilas-Boas, V.D. Araújo, N.F.C. Rodrigues, A. Mendes

Publication Date: 23 August 2024

Category: SAF

Article Link: https://www.sciencedirect.com/science/article/abs/pii/S1385894723010483

DOI: https://doi.org/10.1016/j.cej.2023.142317

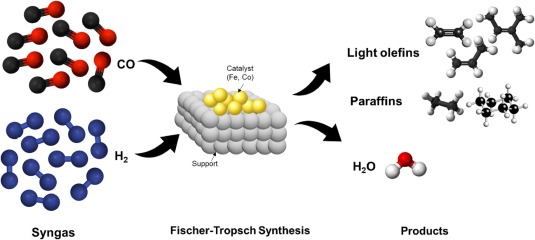

Abstract (Official): This work provides a critical review on the integrated production of eSAF by Fischer-Tropsch in pulp mills. A plant design is proposed and analyzed by considering the most mature and ready technologies, namely: i) CO2 capture by amine absorption, ii) H2 production by water electrolysis, iii) syngas (CO + H2) production by Reverse Water Gas Shift, iv) Low Temperature Fischer-Tropsch and v) Fischer-Tropsch products refining to eSAF. This integration can be implemented today and has the potential to decarbonize approximately up to 10 % of the aviation sector, making it the first step towards the establishment of eSAF production plants.

The most important aspect for the success of the concept is achieving a continuous supply of green and cheap H2. This means that securing low-cost renewable electricity is a precedent condition for any plant based on this design. The integration in pulp mills also shows various potential synergies, being that some of them may be complex to capitalize on but offer substantial benefits. Significant improvements were also identified for each of the main building blocks, however prior technological development and demonstration is necessary before practical implementation in eSAF plants. As a result, first generation plants will produce eSAF that can be 5 to 8 times more expensive than fossil jet fuel, which implies that financial support will be mandatory to ramp-up the market and comply with European targets.

GAT Editor’s Comments:

– SAF versus eSAF: Sustainable Aviation Fuel versus Electro Sustainable Aviation Fuel

– Most SAF produced today is a type of biofuel; Power-to-Liquid (also referred to as eSAF) is a new class of sustainable aviation fuel that is not a biofuel. It is produced through an electrochemical process that uses CO2, water and renewable energy

– Mature technologies for producing eSAFs are reviewed

– Main basis of the Fischer-Tropsch (FT) technology is to convert syngas (CO + H2) to synthetic crude in a catalytic reactor

– This paper evaluates the use of FT technology to process existent biogenic CO2 and green H2 from water electrolysis to produce green fuels

– Low-cost renewable electricity generation is required for the production of green and cost-effective H2

– The pulp and paper industry is a relevant producer of CO2,

– Potential synergies by integrating eSAF production with paper pulp mills but additional development and demonstration is required

– Using these methods, first generation plants may produce eSAF that is 5-8x more expensive than traditional jet fuel, so financial support will be required to enable production ramp up and enable meeting European targets